This is my first attempt at using SMD components. It is also my first attempt at using a toner transfer method , and developing a design using EagleCAD.

I am making a circuit that reads a cheap digital caliper and outputs the values as a keyboard. to be used for CAD programs. It has also been designed to be a business card that prints out a resume.

Before I continue, I must reference the group of projects that I took ideas from in order to begin this little project.

Other Projects of inspiration

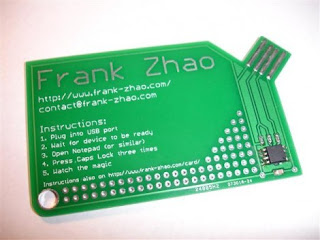

USB PCB Business Card by Frank Zhao

http://www.instructables.com/id/USB-PCB-Business-Card/

Increadible POV PCB Business card with full small scale circuit fab setup.

http://www.instructables.com/id/Circuit-Board-Lab-POV-Business-Card/#intro

Nerdkits DRO the functional part

http://www.nerdkits.com/videos/digital_calipers_dro/

Benito USB to serial

http://dorkbotpdx.org/blog/feurig/build_your_own_usb_to_serial_device

PCB etching youtube tutorials by Anomus:

http://www.youtube.com/watch?v=di5WD7AhVzI

Anomus' blog:

http://aonomus.wordpress.com/

Build Log

|

| These are the parts that arrived from digikey |

|

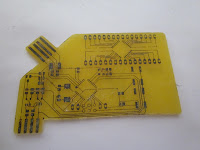

| Board after rubbing off carrier paper and prior to etching |

|

| After the first attempt at etching - note the white areas where papaer remains inbetween busy areas. |

|

| After the toner transfer - looks good, some patchy parts. Particularly some of the traces for the breakout did not transfer properly (center top). |

|

| Final shape cutout |

|

The PCB had to be filed to get it thin enough to fit into the slot on the caliper. I also guestimated the pitch wrong. I will need to fix that in the next revision.

|

|

| Tinned the connectors to make them more durable. |

|

| The final board except for the ICs |

|

The adjustment nut on the caliper conflicts with the header pins. Should have seen that one coming. I will fix that in the next revision.

|

Lessons learnt and improvements for next design.

Design

- Increase DRC minimum spacing from 8mil to 16mil

- Change trace widths to:

- 10mil where passing under components

- 15mil inbetween

- 20mil where space allows\

- Move quad pack back and up to make more room for programming pins

- Adjust caliper tab spacings

- Make pads bigger on ISP 6 pin stack

- Round/fillet corners on the card

- Join USB and caliper connectors

- Adjust caliper outside dimension

- improve ground via for left side

Construction

- More time/heat/pressure to transfer the toner

- more spent removing excess paper after transfer.

- Remember to touch up bad parts with sharpie.

- better control of temperature and dosing.

No comments:

Post a Comment